Commercial Roofing By RGP

With RGP Restoration, Construction & Roofing Group’s vast experience in restoration, construction and roofing over the years, we handle a wide array of commercial roofing products including single ply TPO roofing, modified bitumen, tar and gravel, and metal roofing. Commercial structures differ in their functionality, architecture, and style, and therefore require many different commercial roofing solutions. We would like to give you a brief overview of the various commercial roofing structures that we install on this page with links to more detailed information about that particular roofing product.

Commercial Roof Repair by RGP

Commercial Roof Repair Specialists by RGP

The first line of defense if you are having problems with your commercial roof is to have professionals like RGP inspect the roof and see if a repair is in order. It is wise to have a roof inspection before you can see the actual problems that can be caused by roofing leaks due to hail damage, heavy wind or even tornadoes. Our restoration specialists know what to look for after heavy hail storms, thunderstorms, and damaging wind. The problem is that it takes a trained professional to spot potential problem areas of a commercial roof, and you need someone that knows what to look for. RGP has an licensed Insurance Adjuster on staff that has seen hundreds of commercial roofs with leaks and knows where the problem areas of most commercial roofs are. This means that he is able to spot the problems in your roof and have the solutions to repair your roof before it causes damage, or more damage to your building and potentially your inventory or equipment inside of the building. If your building has experienced a heavy thunderstorm or hail recently, it never hurts to have one of the RGP Professionals inspect your roof for potential damage. It is always best to find and repair minor damage or leaks to your roof before they start to destroy your building and/or inventory below.

Commercial Roof Replacement by RGP

Commercial Roof Replacement by RGP Restoration

After a thorough inspection, many times it is determined that a roof replacement is going to be necessary to fix your commercial building. RGP are experts at many types of commercial roof replacements, including modified bitumen, single-ply TPO, commercial roof coatings, tar and gravel, and metal roofs. The type of roof replacement that you need will depend on the type of roof you currently have, your building structure, and many other factors. There are times when we recommend that are customers change the type of roof that they have to a better quality commercial roof for their individual circumstances. The best way to determine what type of roof replacement you need to install on your building is to have a RGP Roofing Specialists come out for a free inspection. This will help to encompass all factors involved in the roof replacement decision based on your buildings individual circumstances.

Single Ply TPO Roofing by RGP

Single Ply TPO Roofing by RGP

RGP Restoration, Construction & Roofing Group believes that single ply TPO roofing systems are one of the best for flat roofs. Single Ply roofing membranes provide a variety of materials to choose from. Their main characteristic is that they are designed to be installed in one layer. Single-ply membranes can be generally categorized into two groups: Thermosets and Thermoplastics. Thermoset membranes are compounded from synthetic rubber polymers, and the most commonly used polymers are EPDM, CSPE and Neoprene. Two of the most commonly used thermoplastic single-ply membranes are PVC and TPO, both of them plastic-based materials. While RGP is experienced in all types of Thermosets and Thermoplastics, we install a great number of TPO roofing systems because we believe they are very well suited to the Oklahoma weather and environment. To learn more about single ply TPO Roofing systems by RGP, click here.

Commercial Roof Coatings by RGP

HydroStop

RGP carries some of the best commercial roof coatings by some of the top manufactures like GAF and Owens Corning. GAF offers HydroStop PremiumCoat®, which is more than a coating, it offers Liquid Applied Membranes that preserve and protect both new and existing structures. It is a a fabric-reinforced acrylic elastomer that functions as both a stand-alone roof system and a re-cover system. Whether applied to a building’s roof, wall, or hardscape, GAF manufactures reliable coating solutions that building owners and design professionals know they can trust. They feature the United line of coatings which includes acrylics, silicones, and urethane coatings. Their StreetBond™ line of pavement coatings can transform pavement with color and increase solar reflectivity, while also serving to revitalize, rejuvenate, and extend pavement life. Click here to learn more about our commercial roof coatings.

Modified Bitumen Roofing by RGP

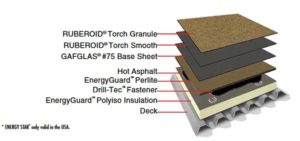

Ruberoid Modified Bitumen by GAF

Modified Bitumen roofing is a type of roofing that is an evolution of asphalt roofing. It is made from asphalt and a variety of rubber modifiers and solvents. There are several ways of connecting pieces of this material. In a heat application process the seams are heated to melt the asphalt together and create a seal. There is also hot-mopped application, similar to how conventional built-up roofs are installed. Cold-applied adhesives and self-adhesive membranes are two of the more recent options. This material is also referred to as APP, SBS, and SEBS. RGP is a big believer in GAF modified bitumen products and you can read more about them and modified bitumen as a flat roofing system by clicking here.

Tar and Gravel Roofing Systems

Tar and Gravel Roof

A tar and gravel roofing systems is often referred to as Built Up Roofing, or BUR. It is a system of flat roofing protection that is cost effective and can last up to 30 years. Tar and gravel roofs are usually made of 3 to 5 laminated layers of asphalt base sheets, hot tar, and roofing felt. A top layer of bitumen and extra top mineral coating is also added. Light colored gravel is used to cover the dark layers. The gravel weighs down the roofing materials, protects the layers against sun damage, and reflects some of the sun’s light. An even layer of gravel must be kept on the roof at all times and some gravel should remain loose to protect your roof from puncturing caused by any foot traffic. Drains and downspouts are also built in to drain any water from the roof. When new equipment is installed on a tar and gravel roof such as an electrical access or an air conditioning unit, special care needs to be paid to ensure the membrane of the roof isn’t penetrated. Resealing the roof is an effective way to prevent leaks caused by new additions to the roof. Click here for more information about tar and gravel roofing systems by RGP.

Metal Roofing Systems

Metal Roofing by RGP

While the initial cost for a premium metal roof is higher than most other roofing materials, you’ll save money in the long run. A metal roof can last a lifetime, whereas materials like asphalt require reproofing every 10 to 20 years. A metal roof can also increase the resale value of your home. The average life of a non-metal roof is 17 years. Asphalt can require re-roofing every 10 to 20 years, often sooner. But a metal roofing system offers unmatched durability, lasting 2 to 3 times longer. There is a good chance that a metal roof will be the last roof you ever install on your home or business. Metal roofing has a variety of styles, shapes, textures and colors and many metal roofs today looks just like other common roofing materials like asphalt shingles, clay tile, cedar shake, or even slate. Metal roofs can also be much more energy efficient than an asphalt shingle because with both light and dark colors, the metal roof will reflect heat effectively to reduce cooling loads in the summer and insulate homes or businesses during the winter. Most metal roofs also have a very good warranty of 30 to 50 years from the manufacture, plus a workmanship warranty from the installer like RGP. Click here to learn more about metal roofing systems by RGP.